Cushions much like the ones on your couch right now are designed to take the impact force that comes from the piston moving quickly and abruptly stop when coming in contact with the Head or Cap. While this can happen occasionally without major damage to the cylinder, over time this impact loading can cause the tie rods to fail due to fatigue loading, or can cause excess compression loading to the piston, head or cap. This causes distortion of these parts which will ultimately lead to cylinder failure.

Read more of this post

FILED UNDER:

Application,

Maintenance,

Innovation,

Quality

Piston sealing is critical to proper cylinder function. Piston seals keep fluid from bypassing the piston which would otherwise reduce the pressure differential across the piston and in turn reduce the available force for the cylinder to perform work.

Read more of this post

FILED UNDER:

Seal Solutions,

Application,

Innovation

One of the very basic elements in designing a cylinder to meet the needs of a machine is the determination of whether or not the cylinder should be a single or double rod cylinder. Each type has its own distinct advantages and disadvantages, and is an important early step in the cylinder design.

Read more of this post

FILED UNDER:

Application

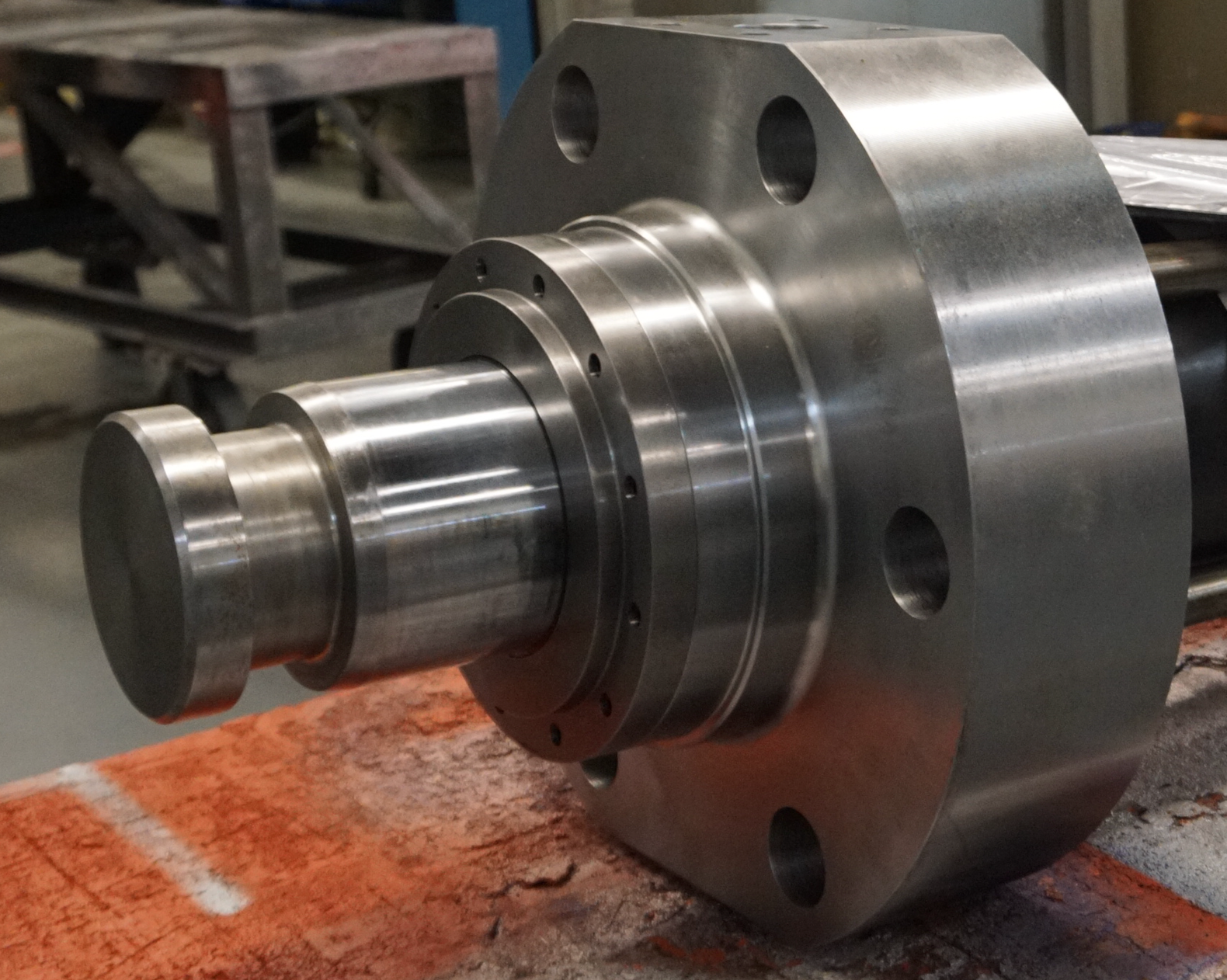

A critical decision to make when designing a cylinder is the size of the bore. The bore is the inner diameter of the cylinder tube, which can also be known as the barrel. The bore size, along with the known operating pressure of the cylinder determines the force output of the cylinder. Many hydraulic systems are designed to run at 3000 psi hydraulic pressure, while most pneumatic systems are designed to run at roughly 100 psi.

Read more of this post

FILED UNDER:

Troubleshooting,

Application,

Quality

Let's take it back to the Basics! Like... what is a Cylinder??? What do all these words mean?! How do I know what to order?? Let me help you with some specifics to cylinders and to our Sheffer line!

Read more of this post

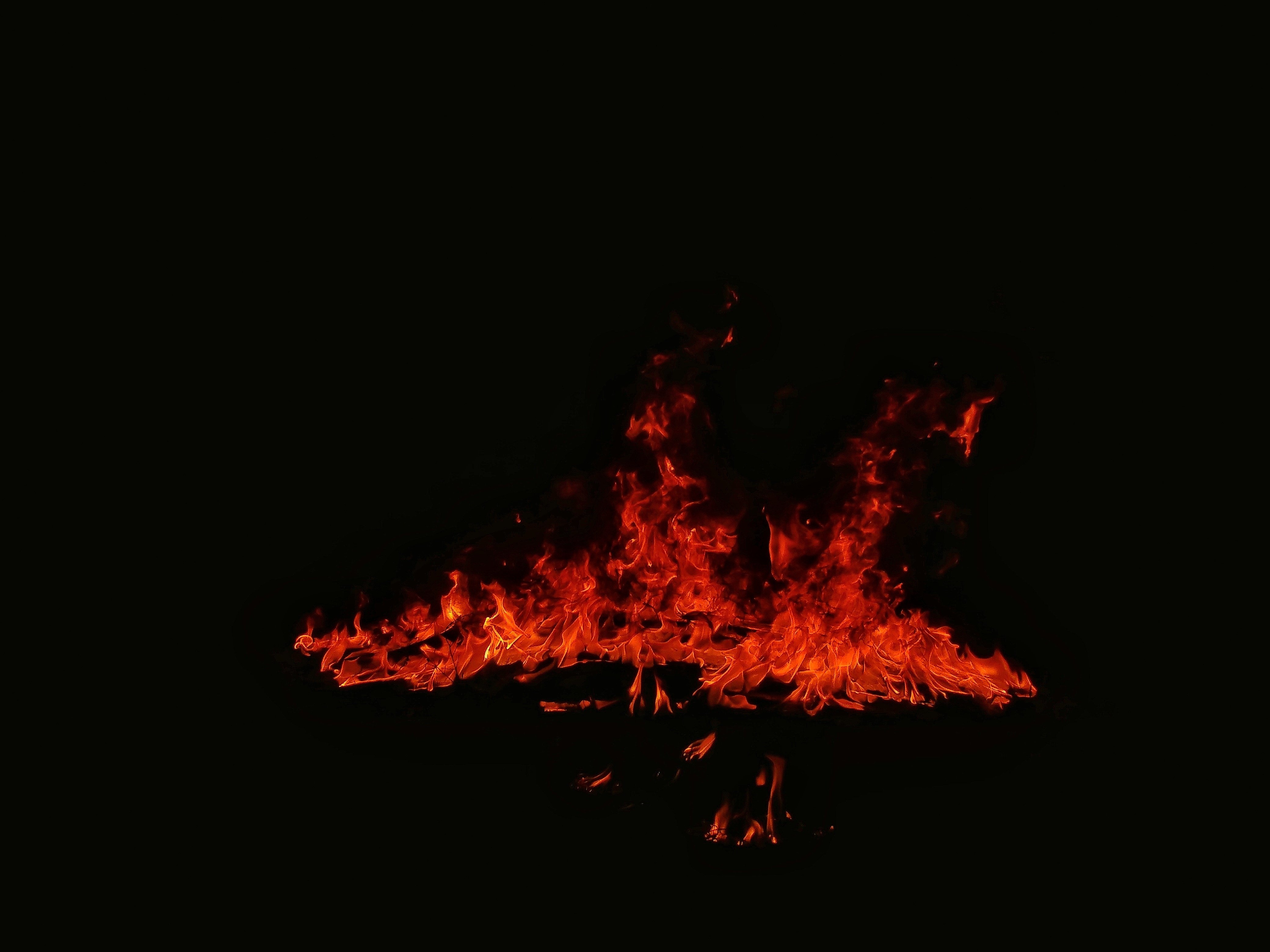

There are many applications where cylinders are exposed to extreme heat due to environmental conditions. Whether your cylinder is near a bakery oven or hanging above a crucible of molten metal knowing which options are available to handle the heat becomes top priority.

Read more of this post

FILED UNDER:

Troubleshooting,

Application,

Failure Analysis,

Quality

Keeping up with production demands is a proven challenge in the lumber industry. To stay competitive, operations demand higher performance and lower cost for automated equipment. Lumber processing end-users want solutions to the problems encountered in the rough environment of the mills where temperatures fluctuate, dust produced from the processes damages your equipment, and grate machinery.

Read more of this post

FILED UNDER:

Application,

Failure Analysis