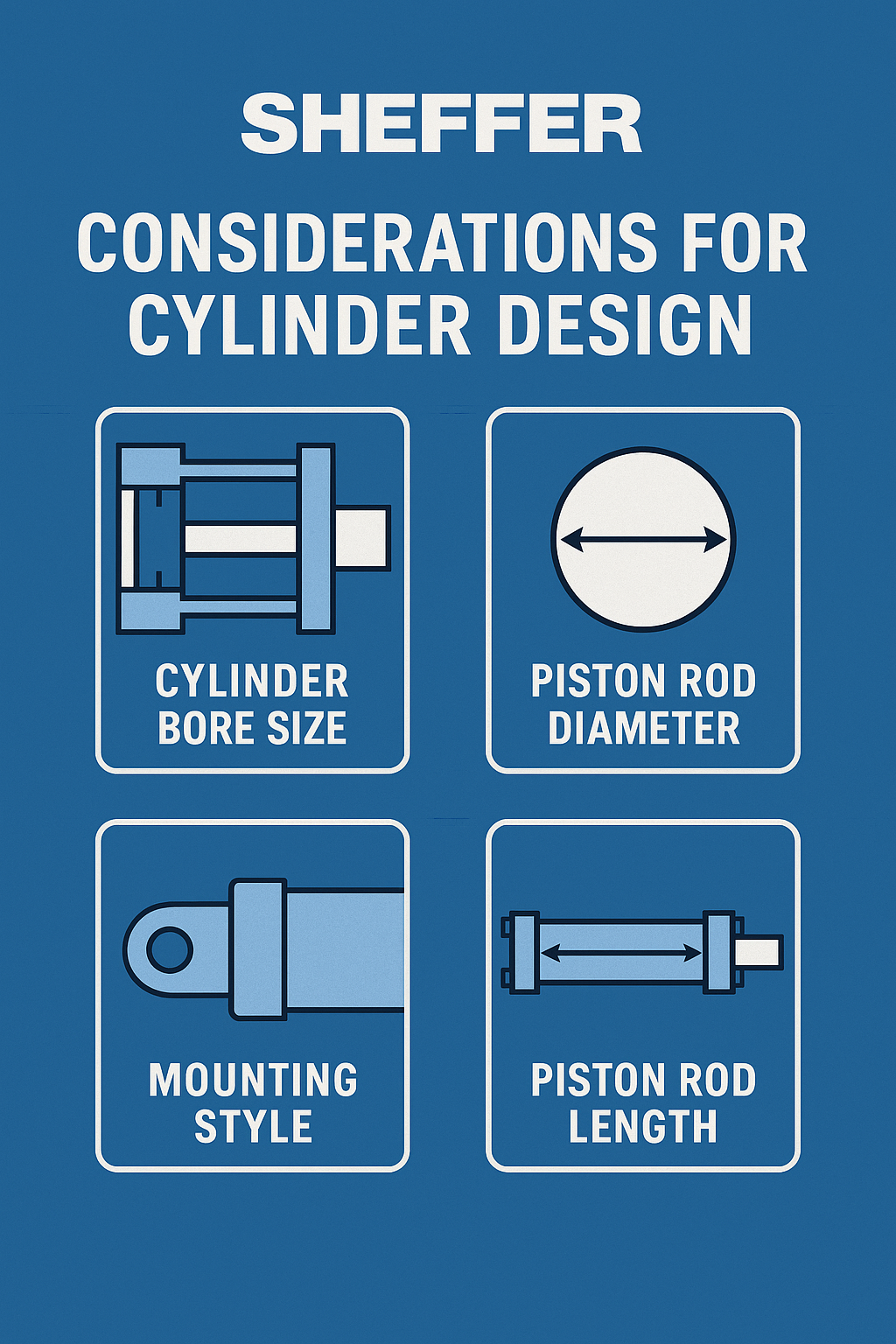

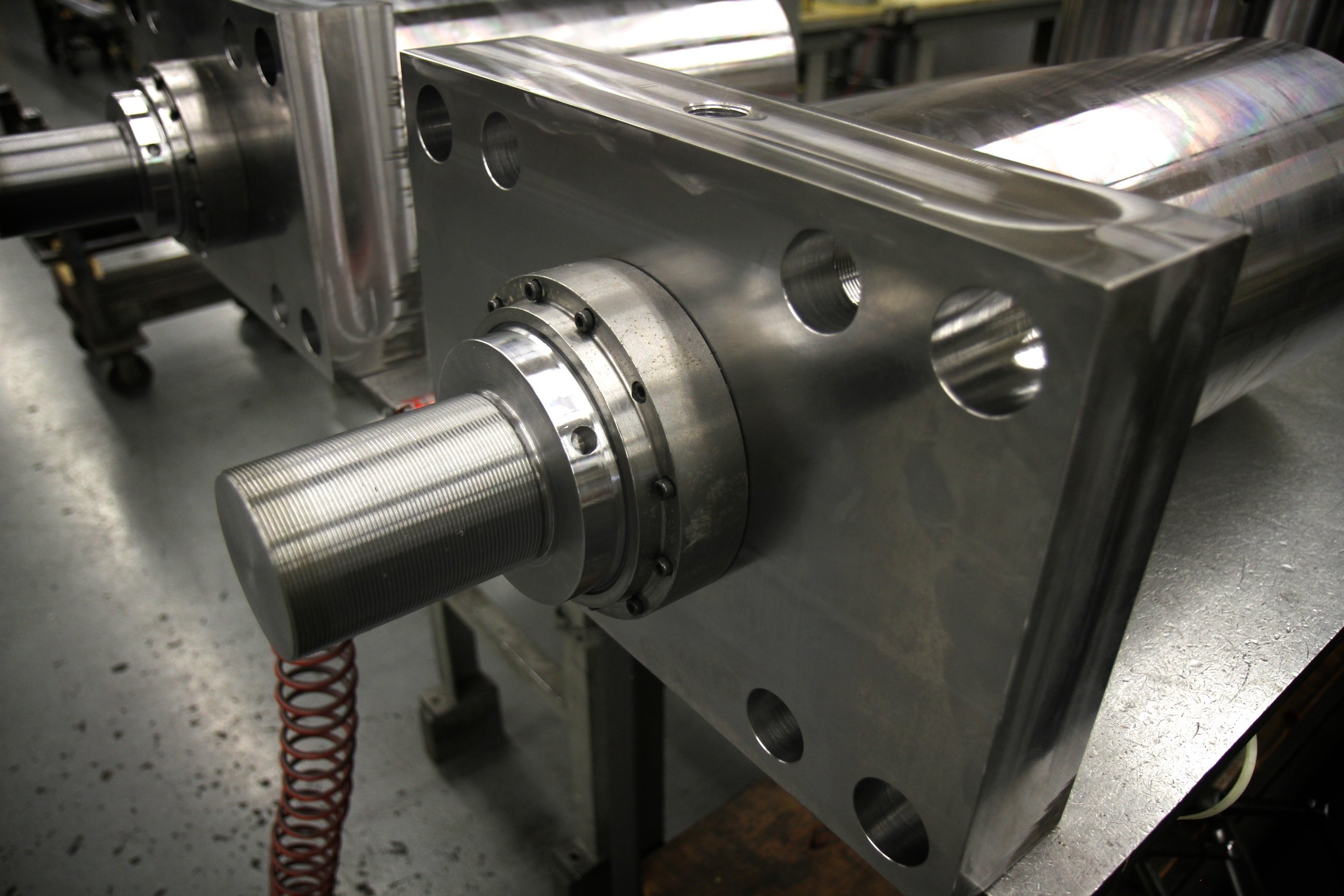

When designing a cylinder, it is important to consider how much force will be on the piston rod as the cylinder is extending. If too much compressive force is applied to the piston rod in extend, it will cause it to bend and buckle. Consider a coffee stirrer. When placed between two fingers and pushed on, it very easily bends. Now consider a drinking straw. While it might be longer, it also has a larger diameter, thus when placed between two fingers and pushed on with the same amount of force it does not bend as easily. In the same way piston rods will bend when the force to rod diameter ratio becomes too large. Several factors contribute to the force, and associated cylinder pressure, when this bending will begin to occur. These factors include bore size, rod diameter, mounting style, length of stroke and extra plain rod extension, and even rod material.