Hydraulic Cylinder in the Pipe and Steel Industry

In the pipe and steel industry, equipment reliability is not optional. Heavy loads, extreme temperatures, and continuous production demands mean every component must deliver consistent performance. Hydraulic cylinders play a critical role in powering the machines that shape, move, and process steel products, helping manufacturers maintain precision, safety, and uptime.

Read more of this post

FILED UNDER:

Application,

Maintenance,

Innovation,

Quality,

Customer Solutions

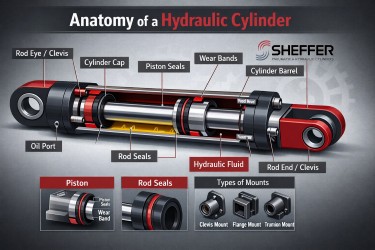

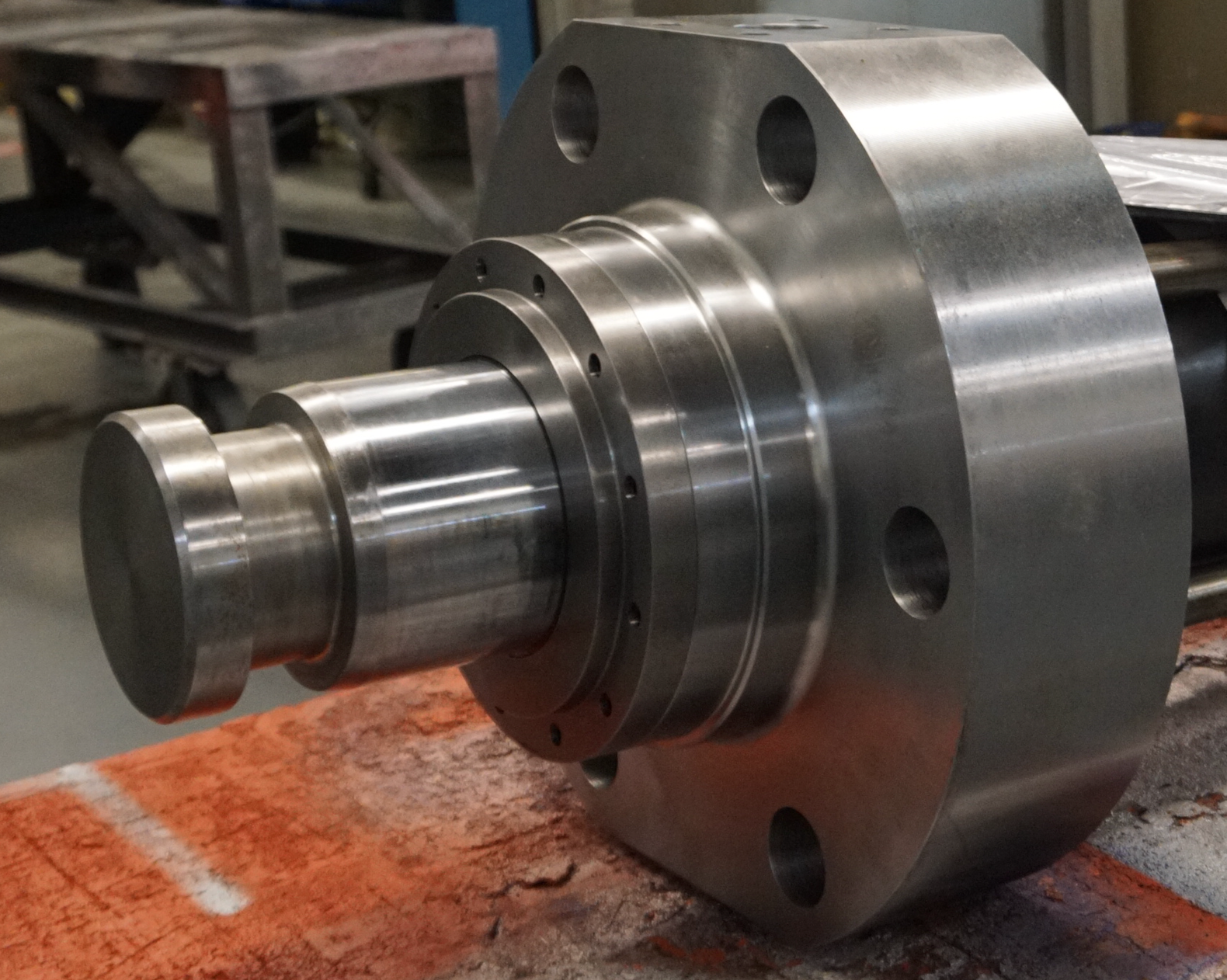

Hydraulic Cylinders are at the heart of countless industrial, mobile, and manufacturing applications. While they may appear simple from the outside, their performance, reliability, and lifespan depend on a precise combination of internal components working in harmony.

Read more of this post

FILED UNDER:

Application,

Innovation,

Failure Analysis,

Quality

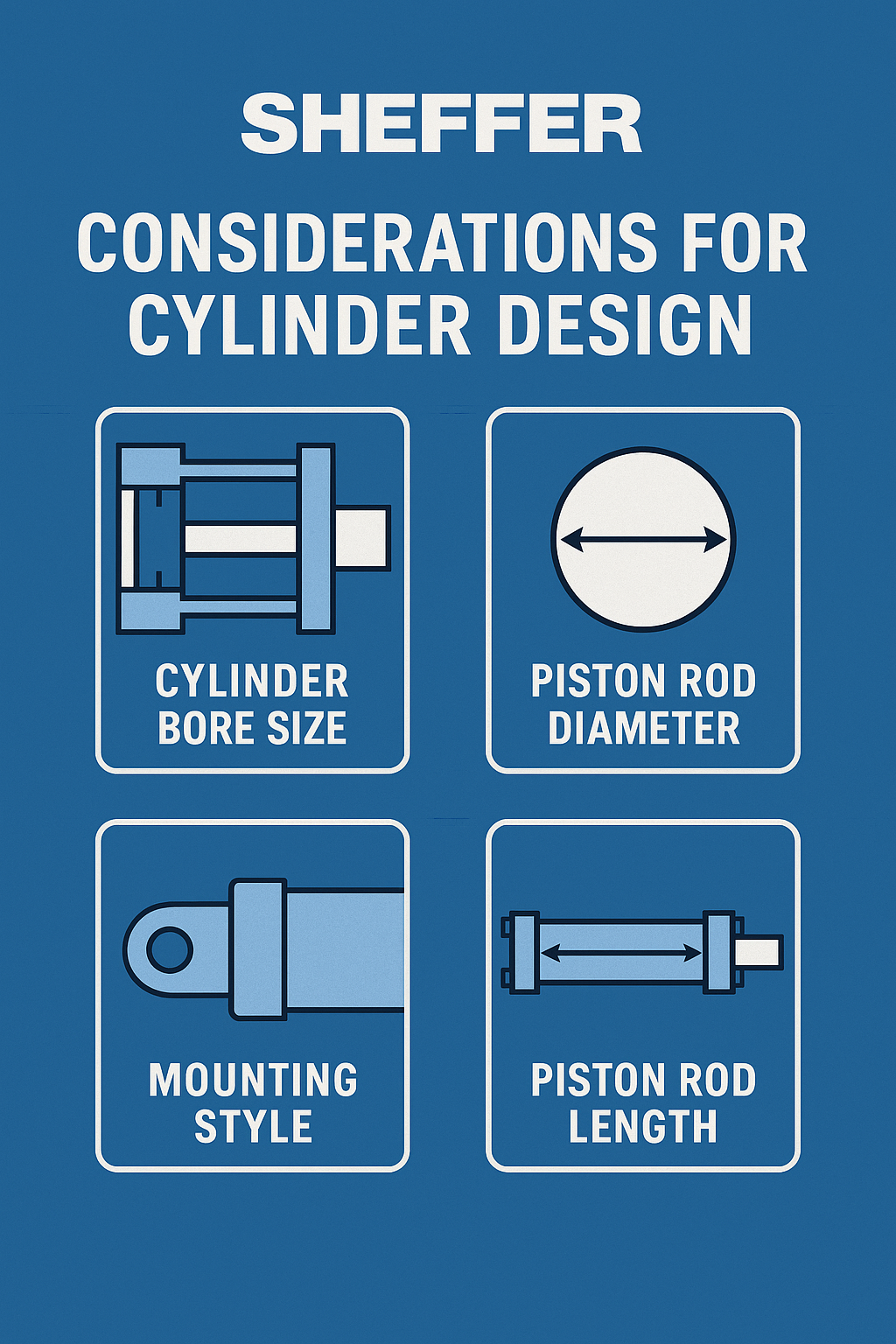

When designing a cylinder, it is important to consider how much force will be on the piston rod as the cylinder is extending. If too much compressive force is applied to the piston rod in extend, it will cause it to bend and buckle. Consider a coffee stirrer. When placed between two fingers and pushed on, it very easily bends. Now consider a drinking straw. While it might be longer, it also has a larger diameter, thus when placed between two fingers and pushed on with the same amount of force it does not bend as easily. In the same way piston rods will bend when the force to rod diameter ratio becomes too large. Several factors contribute to the force, and associated cylinder pressure, when this bending will begin to occur. These factors include bore size, rod diameter, mounting style, length of stroke and extra plain rod extension, and even rod material.

Read more of this post

FILED UNDER:

Troubleshooting,

Application,

Innovation,

Failure Analysis,

Quality

In the fast-paced and high-risk oil and gas industry, having reliable, durable equipment is critical to operational success. At the center of many vital systems lies a key component: the Hydraulic Cylinder. Whether it’s land-based drilling, offshore platforms, or refinery systems, hydraulic cylinders provide the power and control needed to operate safely and efficiently.

Read more of this post

FILED UNDER:

Application,

Innovation,

Failure Analysis,

Quality,

Customer Solutions

Cushions much like the ones on your couch right now are designed to take the impact force that comes from the piston moving quickly and abruptly stop when coming in contact with the Head or Cap. While this can happen occasionally without major damage to the cylinder, over time this impact loading can cause the tie rods to fail due to fatigue loading, or can cause excess compression loading to the piston, head or cap. This causes distortion of these parts which will ultimately lead to cylinder failure.

Read more of this post

FILED UNDER:

Application,

Maintenance,

Innovation,

Quality

A critical decision to make when designing a cylinder is the size of the bore. The bore is the inner diameter of the cylinder tube, which can also be known as the barrel. The bore size, along with the known operating pressure of the cylinder determines the force output of the cylinder. Many hydraulic systems are designed to run at 3000 psi hydraulic pressure, while most pneumatic systems are designed to run at roughly 100 psi.

Read more of this post

FILED UNDER:

Troubleshooting,

Application,

Quality

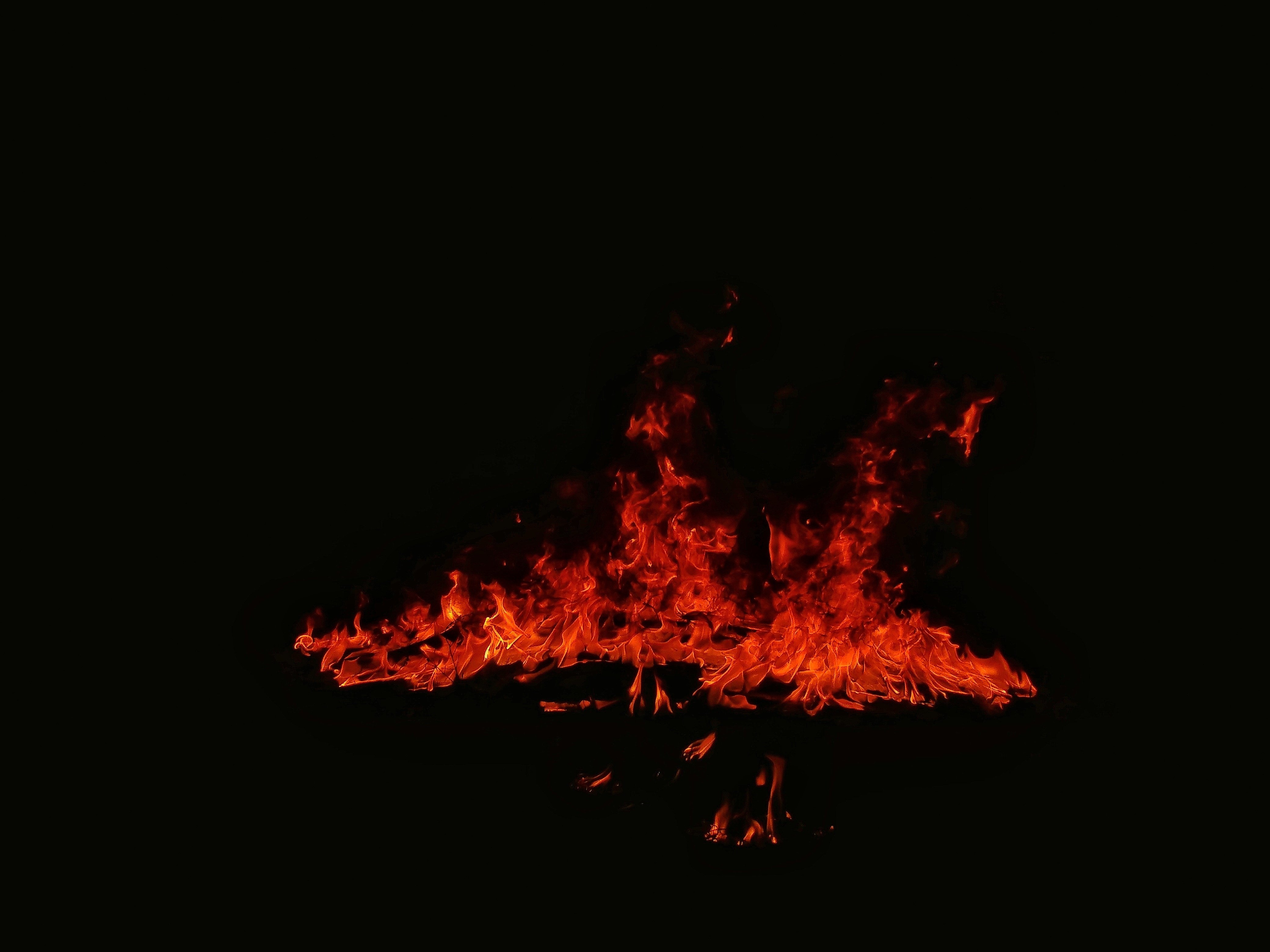

There are many applications where cylinders are exposed to extreme heat due to environmental conditions. Whether your cylinder is near a bakery oven or hanging above a crucible of molten metal knowing which options are available to handle the heat becomes top priority.

Read more of this post

FILED UNDER:

Troubleshooting,

Application,

Failure Analysis,

Quality