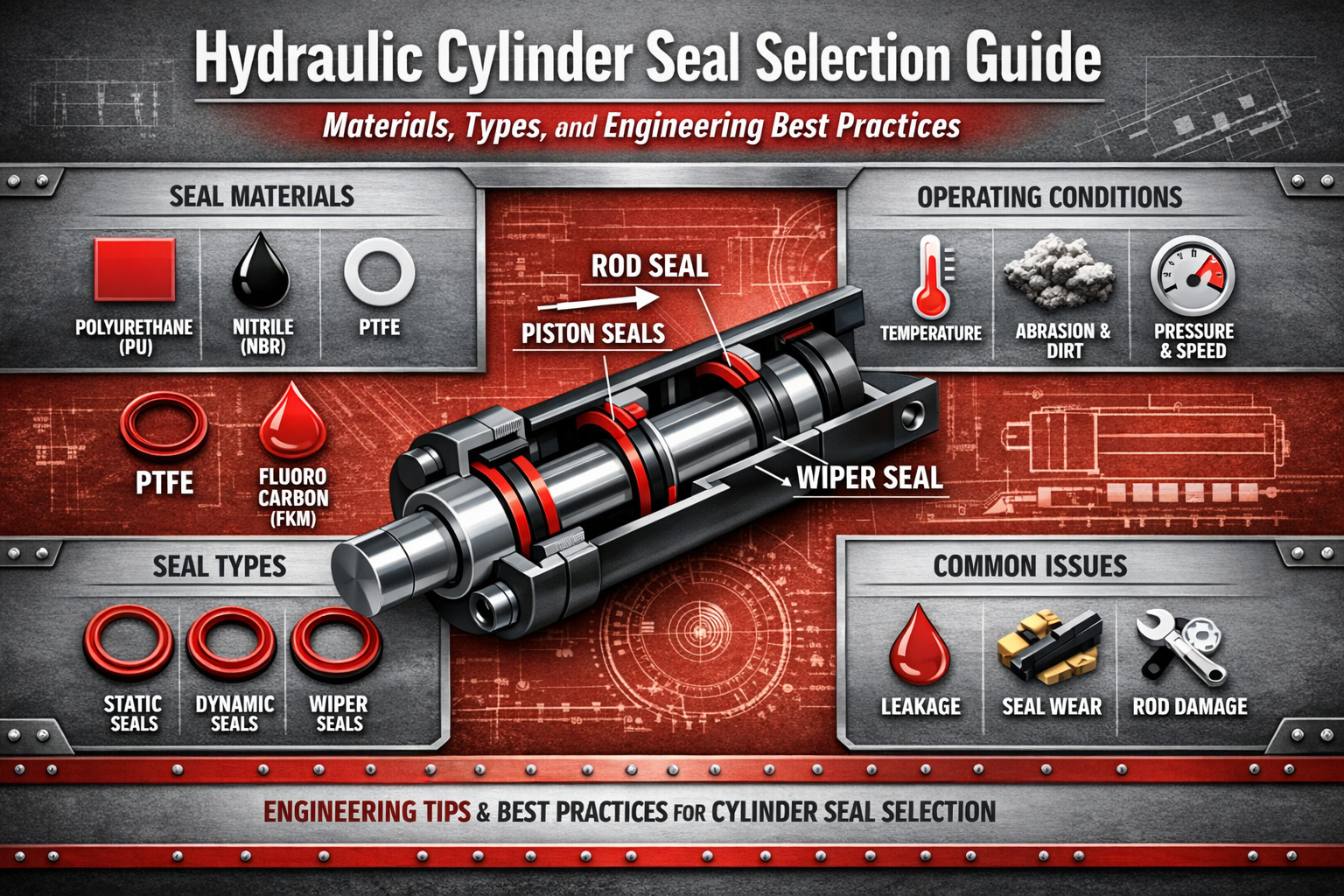

How to Choose the Right Hydraulic Cylinder Seals:

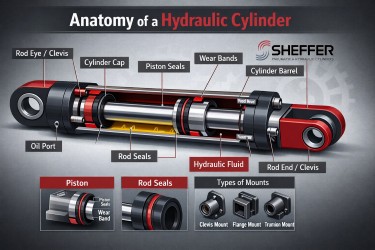

Hydraulic and pneumatic cylinder performance depends heavily on one critical component that often gets overlooked during early design stages: the sealing system. The right seal choice directly impacts efficiency, reliability, maintenance cycles, and overall operating cost. Understanding how materials, environments, and motion dynamics influence seal performance helps engineers avoid premature failures and maximize equipment uptime.

-1.png)