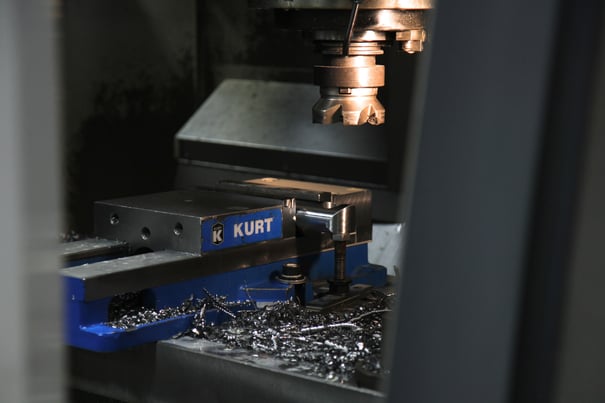

Let’s face it, your maintenance team works hard for you. They put in their eight hours per day, five days per week, and then they are on call the other 128 hours each week that they are not out on the shop floor making repairs. They climb in the machines, deal with all of the dirt and oil, the metal shavings, they go outside to fix the heating system when it is 5° below zero, and are on the roof patching it when it is well over 100° outside. These guys put in the extra hours when the shop is closed to make sure the machines are up and running every day to keeping the parts flowing out, and the money flowing in. Anything management can do to make their lives easier is ALWAYS appreciated. When you are looking at purchasing cylinders for your machines that your maintenance team will have to install and maintain, there are some features you need to make sure you get to make their lives easier.

What happens when the rod thread breaks on your cylinder?

Well, your machine is down, and if you have a replacement cylinder your maintenance guy has to install it. If you don’t have a replacement, your machine is down, and you need a new piston rod, and then your maintenance guy has to rebuild the cylinder with the new rod, or you have to replace the whole cylinder.

What if instead of the threads being machined directly into the rod end there was a threaded stud? Then there would be no thread relief to break, no fear of poor machining in that thread relief leading to fatigue cracks, and if the threads on the stud get damaged, all you have to do is remove the old stud and thread in a new stud, your maintenance guy may not even have to take the cylinder off of the machine! Something your maintenance guy and your bottom line will thank you for. If your cylinders don’t have threaded rod studs, consider asking for them the next time you need to replace your cylinders.

How many wrench flats do your cylinders have?

Many manufacturers make their rod ends with only (2) wrench flats. Sure, you can get the crescent wrench on them, but you have to make a full half turn before being able to reposition the wrench. But the cylinder is in a tight space that only allows for a quarter turn before having to reposition the wrench. Sorry ‘bout your luck but now you have to put a pipe wrench on the rod and risk scratching the chrome and thus damaging the seals as soon as that rod retracts back into the cylinder...

Imagine having (4) wrench flats. Now your cylinder installation in the tight space is much simpler because it is possible to get the wrench on the rod from all angles. If your cylinders don’t have (4) wrench flats demand them next time you need to replace your cylinders.

What happens when you have to replace the rod seals?

With most cylinder manufacturers the rod bearing is integral to the packing gland. This means that if the rod seals ever need to be replaced the cylinder must be removed from the machine, and the piston rod propped up to prevent it from falling and hitting the cylinder head and being damaged. This is just not practical with a 14” diameter bore and 7” diameter rod.

What if the rod bearing was independent of the packing gland? Then the piston rod wouldn’t drop when the packing gland was removed for seal replacement. Even better, you could leave the cylinder mounted in the machine and only disconnect the rod end. Now your maintenance guys are happy, they can get home to dinner with their family tonight, and your machine is back up and running in no time. Insist on an inboard bearing next time you upgrade your cylinders. Your maintenance team will thank you!

Say the cylinder is getting up there in age and it's time to do a complete overhaul and replace all of the seals:

Your maintenance guy has to cancel his weekend plans because it is going to take some time to tear the cylinder down put the new seals in, and then build it back up. And of course since he has to compress the piston seals, your tool maker has to cancel his weekend plans to make an inserter.

But what if the tube had nice big ID chamfers on the ends? Your maintenance guy would be able to quickly reinsert the piston into the tube without fear of damaging the seals, and you don’t have to call your tool maker to come in on Saturday afternoon. Now your maintenance guy and tool maker can make it to that Saturday afternoon pee-wee football game and watch their sons go head to head for the west side championship. If you need special tools to reassemble your cylinders, it’s time that you tell your cylinder manufacturer to do a redesign.

All of these features can make your maintenance guys happy, and your bottom line equally happy. Most cylinder manufacturers offer these as upgrades, if they offer them at all. But the engineers here at Sheffer have incorporated all of them in as standards on all of their cylinders -- you're welcome.